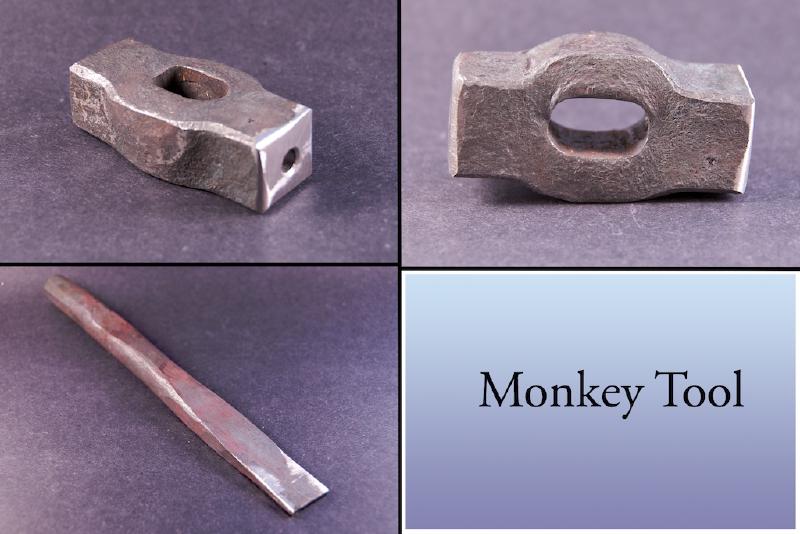

Today, I learned how to make a monkey tool.

Monkey tools facilitate the crafting of tenons - a projection on a piece of metal that’s shaped for insertion into a mortise to make a joint. A monkey tool helps ensure that these tenons are uniform and precise. This tool is especially useful when constructing complex structures or when there’s a need to create multiple matching joints.

The basic procedure for forging one is as follows.

- Begin by chamfering the edges of a 1in square stock.

- Position a slot punch an inch from the corner—this forms the hammer end.

- Carefully align the punch to divide the stock evenly, then tap a few times for initial registration.

- Heat the stock, align the punch with the registration, strike thrice, and then cool the punch in water.

- Rotate 180 degrees and repeat.

- Once nearly punched through, flip the stock and use the slot punch to remove the remaining metal.

- Next, employ a drift to expand the hole to the desired size, starting from the opposite side of the slot, preferably over the hardy hole.

- Dress the faces with the slot still inserted and then chamfer the corners.

- Finally, cut the other end to the tenon’s length and drill a hole of the appropriate size.

That’s it. Out of the four holes I drifted only two came out sort of in the middle